Precision and Excellence in Every Project

At PYPRA Sheet Metal Solutions, we provide a diverse range of precision services, including Turn CNC, Powder Coating, Bending, PEM Insertion, Press Forming, Punching, Assembly, and Laser Cutting. Our comprehensive offerings ensure top-notch solutions for all your sheet metal needs.

What can we do for you?

Here are some of the services we offer, feel free to contact us if you have any questions

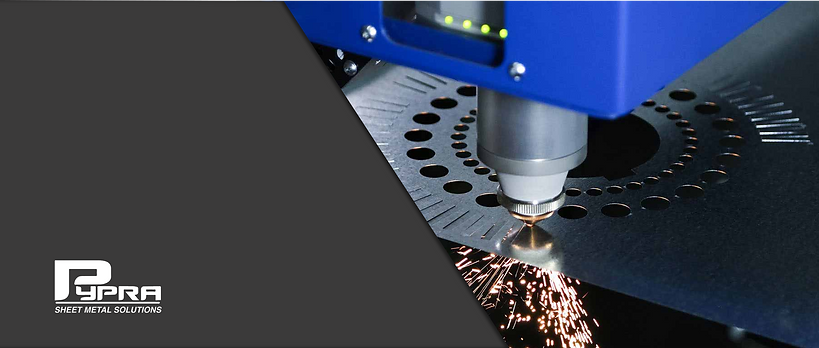

PYPRA provides advanced laser cutting services, a technology that employs a focused laser beam to precisely cut through materials with exceptional accuracy. This versatile method ensures intricate shapes and designs, making it an ideal solution for industries seeking both precision and efficiency in material processing.

PYPRA stands out in both powder coating and metal silk-screening services. Powder coating, a meticulous process, entails applying dry powder to a surface and curing it for a resilient and vibrant finish. This method ensures a consistent coating, providing aesthetic allure and robust protection to diverse materials like metal and plastic.

PYPRA excels in Turn CNC services, employing advanced Computer Numerical Control (CNC) technology to precisely shape and cut materials. This process ensures intricate and accurate designs, making it an essential solution for industries requiring high-precision machining for components and parts.

PYPRA specializes in metal bending services, utilizing precision techniques to shape metals with accuracy and efficiency. Our skilled team employs advanced bending technology to achieve a wide range of angles and forms.

PYPRA excels in assembly services, seamlessly integrating components to create a cohesive and functional end product. Our dedicated team ensures meticulous attention to detail, precision in assembly, and adherence to the highest quality standards.

PYPRA is a leader in metal punching services, employing cutting-edge technology to create precise perforations and shapes in metal sheets. Our state-of-the-art punching processes ensure efficiency and accuracy, making it a versatile solution for various applications in metal fabrication.

PYPRA accelerates precision manufacturing with our cutting-edge press machine, swiftly producing high-quality parts and pieces. Our efficient processes ensure speed without compromising on accuracy, meeting the demands of diverse projects with effectiveness and reliability.

PYPRA excels in PEM insertion services, utilizing specialized techniques to seamlessly integrate PEM fasteners into sheet metal components. This process enhances the efficiency of assembly and ensures robust connections, making it an integral part of our comprehensive metalworking solutions.

PYPRA collaborates with specialized partners for diverse finishing processes, such as nickel plating, tin plating, aluminum anodizing, bluing steel, and many more. This strategic outsourcing ensures our components receive meticulous and high-quality finishes, enhancing durability, corrosion resistance, and overall aesthetics.

Our equipment:

All of our machinery, as well as our processes, are used properly by our professional and highly skilled team. Punching: At our disposal, we have the punch turrets: APELIO 357, VIPROS 255, PEGA 344, and two PEGA 244 units. Bending: In the bending area, we count with the following units: two AMADA PROMECAM HFBD 80, one AMADA PROMECAM FBD, and one CASANOVA D4. PEM inserters: We have two ULYP USUN 618 units, both readily available for use in the insertion of PEM fasteners. CNC: In the CNC area, we have the following: one SHARP SV-6030, one VIPER V-950, two QUASER MF400 units, and one EMCOTURN 365, all operated by our expert employees. Press: For your service, we have a 200 ton HEIM S-200-42-02 press. Misc: As complementary equipment to our other machines, we have an air compressor, two separate stationary routers, as well as a lathe for additional processes and necessary uses.